Artificial Intelligence (AI) in the industry is no longer a distant trend, it has become a concrete reality. In 2023, companies worldwide invested over USD 154 billion in AI-based solutions, according to Statista. The forecast is even more ambitious: by 2034, the market is expected to move over USD 3.6 trillion, with an average annual growth rate of 19.2%.

Combined with data analytics, AI in the industrial sector is accelerating processes, reducing failures, and driving real gains in productivity and competitiveness. In this article, we explain how the technology works in practice and what results it can deliver. Keep reading!

Real-time decision-making on the factory floor

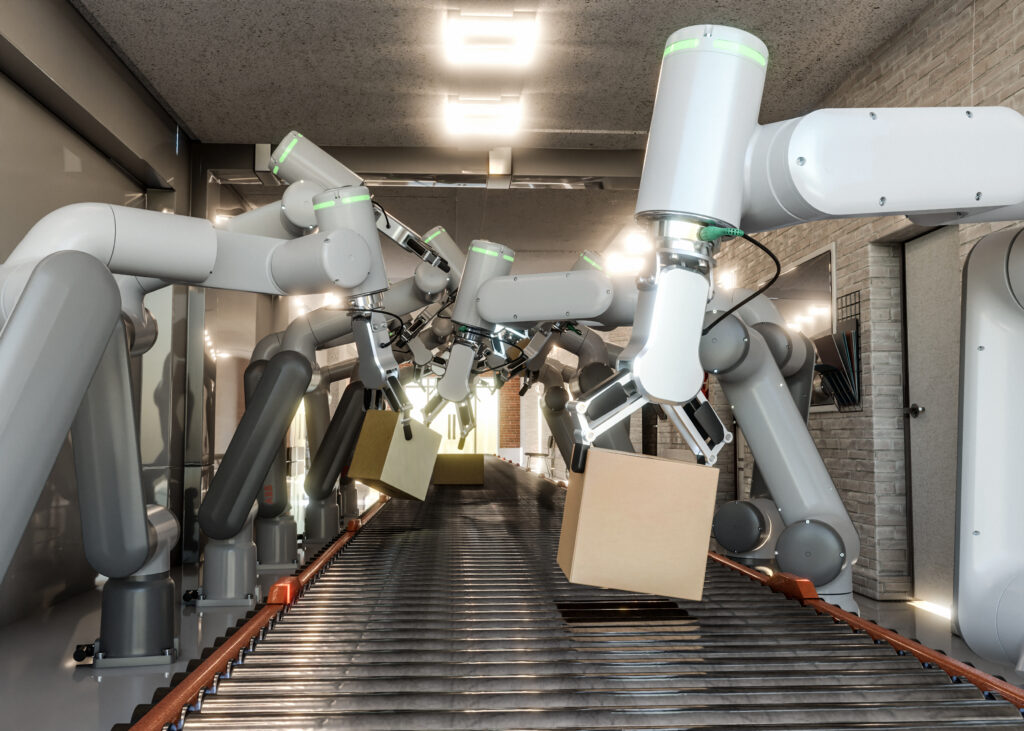

Industrial automation is not new. However, what changes with AI in industry is the ability to make data-driven decisions in real time, without relying on manual commands or fixed rules. AI-based systems can learn from historical patterns and automatically adjust operations when deviations are detected.

In production lines, this means conveyor belts that stop when detecting defects, robots that adapt based on the type of part being processed, or systems that redistribute tasks among machines to avoid bottlenecks. The result is a smoother process, with fewer interruptions and greater consistency in final products.

This intelligent automation also allows the operation to adapt to demand fluctuations. For example, when detecting an increase in orders, the system can suggest changes in production pace and raw material allocation, all based on internal and external data. It’s a way to bring more agility and control without increasing management complexity.

Key applications of Artificial Intelligence in industry

From fast and accurate inspections to optimized supply chain management, AI has a wide range of industrial applications. Here are a few:

Accurate, Fast, and Continuous Inspection with Computer Vision

Computer Vision (CV) transforms industrial cameras into intelligent sensors capable of understanding images, identifying patterns, and making decisions automatically. This technology follows three main steps:

- Identifying specific objects or parts in the image;

- Describing what was found;

- Interpreting the image as a whole by cross-referencing with previously learned patterns.

For example, in an assembly line, CV can identify if a part is correctly positioned, has visual defects (cracks, deformations, or stains), or is outside the expected quality standards. Just like a model trained on thousands of images can learn to distinguish a dog from a cat, an industrial system trained with images of flawless and defective parts learns to recognize what meets or fails quality standards.

The more visual data the system processes (like photos of parts at different angles, sizes, or materials), the more accurate it becomes. As a result, visual inspection moves from being a manual and sampling-based step to an automated, continuous, and scalable process. Efficiency increases, human error decreases, and the operation becomes more reliable.

Anticipating Failures and cutting costs with Predictive Maintenance

Predictive maintenance is one of the most effective applications of AI in industry. It allows machines to “warn” when something isn’t functioning as it should, that is, before a failure actually occurs. This is possible through continuous analysis of data such as vibration, temperature, pressure, and abnormal noise.

With this data, Machine Learning algorithms detect patterns that indicate wear or malfunction. Once anomalies are flagged, the system enables the maintenance team to act strategically, preventing unexpected downtimes and reducing emergency repair costs.

Additionally, predictive maintenance promotes more efficient resource use, extends equipment lifespan, and improves operational predictability, turning operational data into actionable decisions with immediate impact on productivity.

Predictability and control through Supply Chain Optimization

Demands, deadlines, logistics costs, raw material availability… Managing a supply chain is complex due to the need to juggle multiple variables at once. AI becomes an essential tool by helping analyze these variables together and determine the best course of action.

AI helps companies forecast demand spikes, identify seasonal consumption patterns, and even anticipate logistics risks like delivery delays or material shortages. These insights allow for quicker planning adjustments and minimize the risk of excess or lack of inventory.

Another key application is the automatic classification of suppliers based on delivery history, quality, and SLA (Service Level Agreement) compliance. This enhances negotiation transparency and adds security when scaling production.

How our team applies Artificial Intelligence in Industry

AI delivers real results when applied with a focus on data and the real operational context. At BIX Tech, we develop custom solutions for industrial companies facing challenges like unexpected failures, production bottlenecks, and safety risks. Here’s how AI has created a direct impact in efficiency, predictability, and cost reduction across our implemented projects:

Case #1: Cost Optimization in Compressor Lines

Challenge: A motor manufacturer struggled to identify production bottlenecks and understand the impact of station downtimes in the compressor line. Analysis was empirical, leading to unnecessary maintenance and high operational costs.

Our Solution: BIX Tech developed an algorithm that correlates production data with cost indicators. The solution was integrated into an interactive dashboard, simplifying data visualization for stations with the highest operational impact.

Results:

11% reduction in operational losses;

Annual savings of BRL 5 million per activity;

Contributed to WCM cost management certification and replication in other continents.

Case #2: Failure Prediction in Critical Equipment

Challenge: The client faced unexpected equipment failures, hindering production and compromising maintenance resource allocation. The company needed to act proactively.

Our Solution: We developed a real-time failure prediction algorithm, integrated into a dashboard with automated alerts. The tool continuously monitors critical operation variables and issues preventive warnings.

Results:

Significant reduction in unexpected failures;

Faster response from operational teams;

Improved resource management and maintenance planning.

Case #3: Worker Fatigue Prevention

Challenge: The client needed to monitor signs of worker fatigue in real time to ensure safety and prevent accidents in high-risk environments.

Our Solution: BIX Tech created an AI solution capable of predicting fatigue risk up to 4 hours in advance. The system analyzes physiological and environmental variables and presents results via a web platform with alerts and insights.

Results:

Early risk detection through preventive alerts;

A real-time decision-support tool;

Direct contribution to preventing fatigue-related accidents.

Ready to apply AI in your industrial operation?

AI in industry is no longer an experimental project, it’s a strategic tool. With it, you can predict failures, automate decisions, ensure quality, and adapt your entire operation with greater agility, all while maintaining control.

The truth is, companies that adopt AI with planning reap real benefits: lower costs, higher productivity, and more resilient operations. With well-organized data and clear goals, this journey is more accessible than it seems.

Need help with that process? You’ve found your ideal partner!

We develop custom projects tailored to your needs. Get in touch with our expert team and find out how we can transform your industrial operation!